Table of Contents

Introduction

The infrared segment of the electromagnetic spectrum holds immense importance, serving various fields and enabling essential molecular vibration phenomena. In healthcare, food safety, communications, space exploration, astronomy, and defense, infrared optical components are indispensable. Continuous advancements in infrared light sources and materials have made these applications a reality. This article by Noni Optics provides a comprehensive overview of commonly used infrared materials and their practical applications, aiming to assist your IR optics endeavors.

What is Infrared Materials?

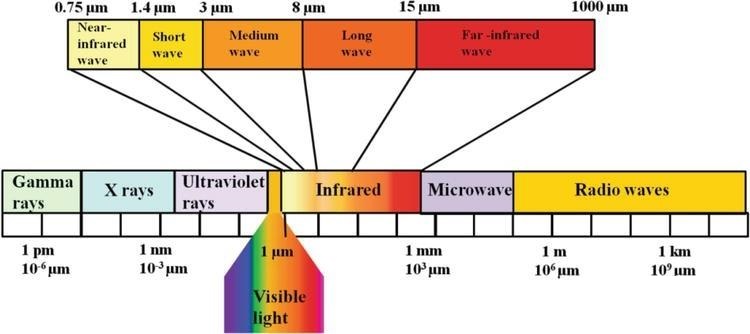

To start, let’s provide a brief overview of infrared (IR). The infrared spectrum lies between the visible and microwave regions of the electromagnetic spectrum. In terms of wavelength, it ranges from 0.75 microns (abbreviated as μ) to 15 microns. The infrared spectrum is usually divided into 4 sub-bands: near infrared (NIR), short wave infrared (SWIR), medium wave infrared (MWIR) and long wave infrared. (LWIR.)

Each sub-band has different wavelength ranges and specific applications in the electromagnetic spectrum. Here are some common infrared sub-bands and their wavelength ranges:

Near infrared (NIR): 0.75–1.4μm

Features: The transition region between visible light and near-infrared bands, often used for spectral analysis, remote sensing, medical imaging and other applications.

Shortwave Infrared (SWIR): 1.4–3μm

Features: Suitable for infrared spectroscopy and remote sensing applications, usually used in fields such as liquid analysis, material identification and night vision equipment, and often used in applications such as long-distance communications. In this band, the absorption of water begins to increase significantly and therefore has specific material recognition capabilities.

Mid-wave infrared (MWIR): 3–8μm

Features: Used in thermal imaging and military applications, usually used to detect and identify heat sources, fire control systems, etc. This band is commonly used in infrared tracking and guidance systems, especially in passive infrared guided missile technology.

Long Wave Infrared (LWIR): 8-15μm

Features: Mainly used for infrared thermal imaging, thermal sensing and remote sensing, capable of detecting thermal radiation on the ground and in the atmosphere. This is the primary area for thermal imaging, often used in applications such as forward-looking infrared (FLIR) systems.

How to Choose Right IR Material

Choosing the right optical materials is a critical aspect of infrared optical design. Unlike visible radiation, traditional optical materials like optical glasses and plastics are not suitable for the infrared spectrum due to their high light absorption coefficients. In the infrared range, it’s essential to opt for special materials with minimal absorption coefficients. When selecting the appropriate infrared material, consider three key points. While the decision-making process is simpler for infrared materials, the limited options can result in higher costs due to manufacturing and material expenses.

- Thermal properties: Infrared optical materials are often used in environments with changing temperatures, and some infrared applications generate large amounts of heat. Therefore, the coefficient of thermal expansion (CTE) and refractive index gradient of the material need to be evaluated to ensure that optical properties are maintained at different temperatures. Materials with high CTE, such as germanium, may require additional care to avoid degradation of optical performance in high temperature environments.

- Transmission: Infrared optical applications operate in different infrared bands, so appropriate materials need to be selected for the specific band. Different infrared substrate materials show better performance in different wavelength bands. For example, germanium performs well in the mid-wave infrared, while sapphire performs well in the near-infrared.

- Refractive index: The refractive index of infrared materials changes much more than that of visible light materials, which provides greater design freedom for optical systems. However, since infrared materials are limited to a small part of the infrared band, especially when applying anti-reflective coatings, materials suitable for the specific band need to be selected.

By considering these factors, the best optical material for a specific IR application can be selected, ensuring performance and efficiency.

Optical Properties of Common IR Materials

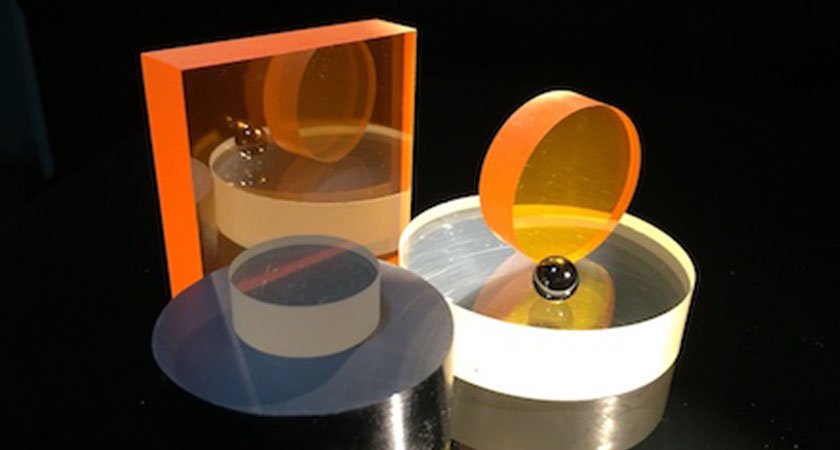

While numerous infrared materials are available, only a handful are widely utilized in the optics, imaging, and photonics industries to craft readily available components. In the following sections, we will delve into the optical characteristics and application scenarios of commonly used infrared materials, including calcium fluoride, fused quartz, germanium, magnesium fluoride, sapphire, silicon, zinc selenide, and zinc sulfide, among others. To conclude, we offer a comparative list of the properties of these materials for your reference.

.1 Fused Silica (IR ) /Transmission Range:0.18-3.5μm

IR grade fused silica substrates are virtually devoid of OH ions, resulting in exceptional transmittance within the 2.7μm wavelength “water zone” region. This is particularly advantageous as standard UV grade fused silica typically absorbs light in this range. With its low OH content of less than 1 ppm, IR-grade fused silica effectively broadens its usable spectrum to 3.6 microns. Much like other categories of fused silica, IR grade maintains the same high standards of uniformity, minimal bubble presence, low coefficient of thermal expansion, and resistance to chemical factors.

.2 Sapphire( Al2O3 )/Transmission Range:0.17-5.0μm

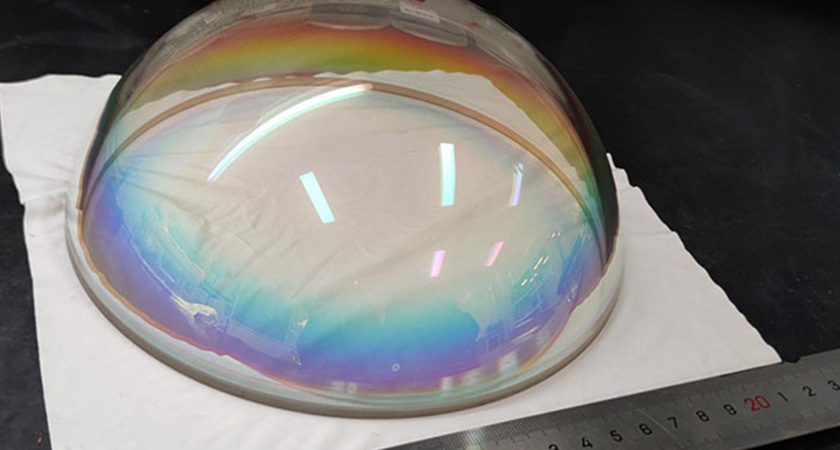

Sapphire, renowned for its exceptional hardness, stands out as a premier choice for infrared applications due to its remarkable mechanical strength, scratch resistance, and resilience against abrasion. Its optical properties enable light transmission across a wide spectrum, ranging from the ultraviolet (UV) to the mid-wavelength infrared (MWIR) at approximately 150 nm. Sapphire optics also exhibits impressive performance in the infrared region, particularly around 5 µm. A distinctive feature of sapphire is its exceptionally low thermal emissivity at elevated temperatures, making it emit less thermal radiation than alternative materials. This property renders sapphire suitable for crafting cavity windows capable of withstanding high temperatures, ideal for passage windows in the infrared band. However, it’s important to note that sapphire’s drawbacks include its relatively high material cost and the technical challenges associated with optical processing due to its exceptional hardness.

.3 Calcium Fluoride ( CaF2 )/Transmission Range:0.15-9.0μm

Optics made from calcium fluoride substrates are ideal for a variety of ultraviolet (UV), visible or infrared (IR) applications. Its low refractive index reduces the need for anti-reflective coatings. Its applications range from thermal imaging systems to excimer lasers, making it a versatile material suitable for ultraviolet (UV) to infrared (IR) frequencies.

.4 Magnesium Fluoride ( MgF2 )/Transmission Range:0.13-7.0μm

Magnesium fluoride, a crystalline substance, exhibits strong light transmission capabilities across a wide spectral range, spanning from ultraviolet to mid-wave infrared wavelengths (0.1 to 7.0μm). While it performs well in the mid-wave infrared (MWIR) band, it may occasionally exhibit unwanted scattering effects, potentially leading to reduced contrast and off-axis stray light concerns. Notably, magnesium fluoride is a cost-effective option, as it can be produced through crystal growth or “hot pressing” techniques. However, it does possess heat sensitivity and demands special handling precautions for optimal use.

.5 Germanium(Ge)/ Transmission Range:2-17μm

Germanium is a gray opaque crystalline material and one of the most commonly used infrared materials. It is the best material for night vision and thermal imaging systems in the mid-wave infrared and long-wave infrared bands. Germanium optic works best between 8 and 12 µm. Germanium has low optical dispersion and a high refractive index, making it an ideal solution for wider field-of-view lenses.

Germanium is a crystalline material, produced as either a single crystal or as a polycrystal. Depending on the growth process, single-crystal germanium is more expensive than polycrystalline germanium. The refractive index of polycrystalline germanium is not uniform enough, which is mainly caused by impurities at the particle boundaries. These impurities will affect the image quality of the FPA. Therefore, single-crystal germanium is called the first choice. At high temperatures, germanium materials become absorptive, with the transmittance approaching zero at 200C.

Its crystal structure is similar to diamond, and when a DLC coating (Diamond-Like Carbon) is applied, it becomes extremely durable and resistant to outdoor elements and harsh environments.

.6 Silicon ( Si )/Transmission Range:1.2-10、50-100μm

Silicon, akin to germanium, is a crystalline material that excels in optical applications, particularly in the mid-wave infrared (MWIR) spectral band ranging from 3μm to 5μm. It serves as an ideal choice for windows and lenses, finding applications in imaging, biomedical, and military fields. Notably, silicon optics exhibit greater heat resistance compared to germanium optics. Germanium optical devices tend to experience degradation in optical performance when operated at temperatures exceeding 100°C.

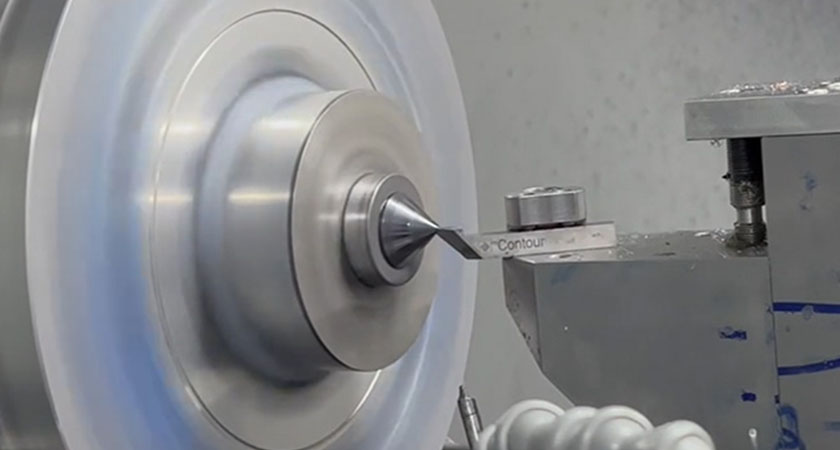

Silicon boasts a refractive index slightly lower than that of germanium, but it remains sufficiently large for effective aberration control. Moreover, it features relatively low dispersion. A notable advantage of silicon is its compatibility with diamond-turning processes, enhancing its versatility in optical applications.

Chalcogenide glasses form another category of materials renowned for their excellent infrared performance. However, it’s important to note that their manufacturing process demands stringent safety measures due to their hazardous material composition. These glasses comprise one or more chalcogen elements, such as sulfur, selenium, and tellurium, but not oxygen. Despite their unique composition, chalcogenide glasses maintain an amorphous structure while delivering exceptional optical transparency across the infrared spectrum, spanning from 2-20μm.

.7 Zinc Selenide ( ZnSe )/Transmission Range:0.55-20μm

Zinc selenide is a widely used material that covers both the visible and infrared spectrums, encompassing the MWIR (Mid-Wave Infrared) and LWIR (Long-Wave Infrared) ranges, from 0.45 to 21μm. This light yellow solid compound is composed of zinc and selenium and bears similarities to zinc sulfide in various aspects. While its refractive index is slightly higher than that of zinc sulfide, its structural strength is not as robust. Therefore, in some cases, a thin layer of zinc sulfide is deposited onto a thicker zinc selenide substrate for improved environmental durability. One notable advantage of zinc selenide is its exceptionally low absorption coefficient, making ZnSe optics a preferred choice for high-energy CO2 laser systems and similar applications.

.8 Zinc Sulfide( ZnS )/Transmission Range: 0.37-14μm

Zinc sulfide is a frequently employed material for applications in the Mid-Wave Infrared (MWIR) and Long-Wave Infrared (LWIR) spectral regions, with optimal performance typically observed in the 8 to 12μm range. Its appearance is generally a rust-yellow hue and it remains translucent to visible light. Zinc sulfide is most commonly produced through a method known as chemical vapor precipitation. While it tends to be more cost-effective compared to Zinc Selenide (ZnSe), it does not offer a longer transmission range. Thanks to its robust and stable properties, zinc selenide is highly resistant to wear from particles, making ZnS optics an excellent choice for use in infrared windows on aircraft platforms.

.9 Sodium Chloride (NaCl) /Transmission Range: 0.23-12 μm

Sodium chloride (NaCl) is a transparent material widely used in optics with a wavelength range covering the visible and infrared spectrum, extending from 0.2 microns (UV) to 20 microns (LWIR). Its high refractive index makes it suitable for use in the manufacture of lenses and windows, while its low absorption properties make it competitive in applications such as spectroscopic instrumentation. Its structural stability and excellent thermal properties make it the optical substrate of choice for high temperature environments and thermal sensor applications.

Infrared Comparison

For your convenience and ease in selecting the right materials for your IR applications, we have prepared a comparative table featuring the 9 most frequently utilized IR materials. This table may significantly simplify your IR material selection process.

| Name | Transmission Range(μm) | Refractive Index | Properties | Typical Applications |

| Fused Silica (FS) | 0.18-3.5 | 1.458@4μm | Low CTE and Excellent Transmission in IR | Used in Interferometry, Laser Instrumentation, Spectroscopy |

| Sapphire (Al2O3 ) | 0.17-5.0 | [email protected]μm | Very Durable and Good Transmission in IR | Used in IR Laser Systems, Spectroscopy, and Rugged Environmental Equipment |

| Calcium Fluoride (CaF2) | 0.13-9.0 | 1.4096@4μm | Low Absorption, High Refractive Index Homogeneity | Used in Spectroscopy, Semiconductor Processing, Cooled Thermal Imaging |

| Magnesium Fluoride (MgF2) | 0.13-7.0 | 1.349@4μm | High CTE, Low Index of Refraction, Good Transmission from Visible to MWIR | Used in Windows, Lenses, and Polarizers that Do Not Require Anti-Reflection Coatings |

| Germanium (Ge) | 2.0-17 | 4.025@4μm | High nd, High Knoop Hardness, Excellent MWIR to FIR Transmission | Used in Thermal Imaging, Rugged IR Imaging |

| Silicon (Si) | 1.2-10/50-100 | 3.4289@4μm | Low Cost and Lightweight | Used in Spectroscopy, MWIR Laser Systems, THz Imaging |

| Zinc Selenide (ZnSe) | 0.55-20 | 2.4332@4μm | Low Absorption, High Resistance to Thermal Shock | CO2 Laser Systems and Thermal Imaging |

| Zinc Sulfide (ZnS) | 0.37-14 | 2.252@4μm | Excellent Transmission in Both Visible and IR, Harder and More Chemically Resistant than ZnSe | Used in Thermal Imaging |

| Sodium Chloride (NaCl) | 0.23-12 | 1.522@4μm | Water Soluble, Low Cost, Excellent Transmission from 250nm to 16μm, Sensitive to Thermal Shock | Used in FTIR spectroscopy |

Conculsion

In summary, there are many material options available for infrared capabilities, and whether you need windows, prisms, lenses or freeform optics, NONI Optics can help you find a solution to achieve your goals. Our superior custom optics service can meet your needs in mirrors, lenses, prisms, aspherical lenses and prototypes with all these IR materials. So please contact us today to discuss your next project.