CNC Grinding

Grinding Spherical and Aspherical Shapes

At Noni, we have highly skilled engineers to operate the CNC grinding machines. With some specific setup of professional calculation, both spherical and aspherical optical components are shaped with initial high accuracy. And the whole process ensures a quick turnaround.

Processing Both Regular and Complex Surfaces

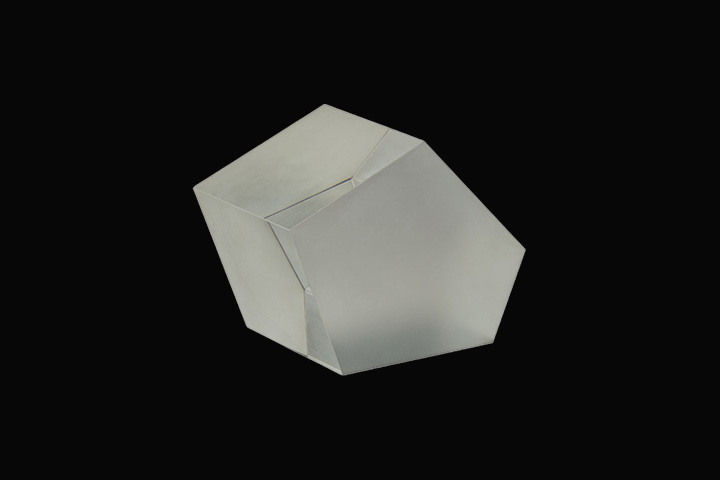

In addition to common optical surface profiles, Noni excels at machining complicated or irregular flat surfaces with exceptional quality. No matter the optical components of oval, polygonal, or other corners with specific radii, they are achievable in our grinding process.

High Precision for Diameters from 20 to 400 mm

Down to diameters of 20 mm or up to diameters of 400 mm, Noni is capable of grinding the ideal profiles and structures with utmost precision. Whether your custom optics are of small sizes or large specifications, the machining challenges will be solved properly.

Supporting the Machining of All Materials

Optical glasses, infrared materials, plastic, and metal, all are processable in our CNC grinding work stage. And we ensure to make the most of all those optical materials. Not to mention that the custom optics of those materials we grind are guaranteed to perform well even in demanding applications.

Check the Product Gallery We Help to Process

The vivid custom optics examples from which you can have a sense of what we are capable of.

FAQ, Your Handy Product Guide

Some important information you might want to know.

Do you offer standard optic components (Shelf Products) ?

No, we don’t sell shelf products. We offer customization service according to your requirements for specific projects or brands equivalent.What substrates do you use for custom optical components?

Our most frequently used substrates are Zinc Selenide (ZnSe), Zinc Sulfide (ZnS), Silicon, Germanium (Ge), Copper, Aluminum, Mo, PMMA, Chalcogenide Glasses, etc.Can you help to customize according to samples we offered?

We highly recommend producing according to specific drawings. Since there are lots of indexes which can not be obtained by measuring samples, such as requirements of material.What's your MOQ for customized projects?

We set very low MOQ for customization projects. But of course, price will be quoted according to the quantity to cover our production cost.How to protect my personal information and our technical information?

Don’t worry, we will sign the NDA with all our customers if needed.What shipping methods are available?

We commonly use UPS, FedEx, DHL, TNT, SF, EMS etc. We also accept your own appointed forwarder.What's the lead time for sampling, for mass production?

For customization projects, sampling lead time will be 1 to 2 weeks. For mass production, 1 to 2 months for orders with quantity 1000 to 2000 pieces.Can you offer all the Certificates required by our customs and our company?

Every product that leaves the factory has been carefully tested. We would like to offer you all the certificates required by your side. Such as:-

Raw material certificate and technical drawing

-

RoHS Report of substrate

-

Inspection report (data) of 3D optical profiler, surface flatness etc.

All products delivered by us will be carefully cleaned and packaged.-

Get A Free Custom Quote

*Your privacy will be 100% confidential at Noni.

View More Manufacturing Capabilities of Noni

Design Coordination >

Design Coordination >As per your spec. sheet, we choose the best process and cost solution for your program.

Pitch Polishing >

Pitch Polishing >Our conventional polishing is ensuring detailed quality for spherical and large optical surfaces.

Diamond Turning >

Diamond Turning >With in-house single point diamond turning machines, we’re poised to process your challenging optics.

Custom Optical Coating >

Custom Optical Coating >All coatings are processed within Noni and totally high quality for correct optical effects.

Special Optics Customization >

Special Optics Customization >Supporting special custom needs like unique shapes, sizes for scientific and institute use.

Metrology and Testing>

Metrology and Testing>We test both before and after coating, and cover all methods making sure precise spec.